- Beranda

- Komunitas

- News

- Sains & Teknologi

DST (Drill Stem Test) in Petroleum Industry

TS

okbrur

DST (Drill Stem Test) in Petroleum Industry

-Bismillahirrohmanirrohiym-

Sharing Knowledge Gans,

DST (Drill Stem Test) in Petroleum Industry

Cekidot no repsol gan,

Norepsol:

DST (Drill Stem Test) merupakan salah satu test dari berbagai macam test yang dilakukan dalam penyelesaian (Completion) sumur pemboran, biasanya dilakukan pada Sumur Explorasi Migas. Data tersebut sangat krusial dalam penentuan cadangan migas suatu lapangan migas.

Original Theory & Practices

Drill stem testing

Introduction

A drill stem test (DST) is a temporary completion of a wellbore that provides information on whether or not to complete the well. The zone in question is sealed off from the rest of the wellbore by packers, and the formations' pressure and fluids are measured. Data obtained from a DST include the following:

This article focuses on nonflowing DSTs (NFDSTs). In a NFDST, fluid does not flow to the surface and a stabilized flow rate is not obtained (also, the well can flow to the surface but die or be shut-in before steady-state rates are achieved). Analysis of flowing DSTs is less complicated because flow rates can be measured throughout the test

Planning

The key to successful testing depends upon planning and teamwork between the geoscientist and the engineer. Potential pay zones should be identified before drilling commences so that the drilling program can be designed to accommodate the test. If offset data are available, the magnitude of porosity, permeability, and reservoir pressure should be identified. Knowledge of zonal mineralogy may prevent excessive damage by drilling fluids and should be used in designing the mud program. The anticipated reservoir properties are used to design the test string and test times so that the best, most useable data can be obtained.

Safety

Running a DST is one of the most dangerous jobs in the oil field because the well is essentially uncontrolled during the test. All fire fighting equipment and the blowout preventers should be inspected and tested before starting a DST. Hydrogen sulfide (H2S) equipment should be on hand if anticipated conditions are sour. No test should be initiated at night or during an electrical storm. No smoking should be allowed on the drill floor or near any flowlines or surface test equipment.

Packer seats

The best time to run a DST is just after drilling through a potential pay zone, when exposure to damaging fluids is minimal and the hole is in its best condition for a good packer seat. Packer seats are generally located in competent sandstones or carbonates above the test interval or both above and below it. The packer seat is picked by the geoscientist or mudlogger using cuttings and the rate of penetration (ROP) as guides. Soft formations, characterized by a fast ROP, usually do not make good packer seats because the packer has trouble seating or gripping the side of the borehole. This results in poor pressure seals, or in extreme cases, the packer may slide down the hole.

Length of test interval

The length of the test interval should be short so that less mud will be displaced from the rathole (the portion of the open hole below the bottom packer) into the drill string.

Length of test time

The length of flow and shut-in periods during the test are critical to obtaining good reservoir data. The dual flow, dual shut-in test is most commonly used. The initial flow period of 3-5 min removes the “supercharge” effect of mud filtrate near wellbore. The first buildup is run for 60 min to determine a valid P* (reservoir pressure). The second flow period is used to collect a fluid sample and create a pressure disturbance at a distance beyond any damaged zone. The duration of the final flow period may be anywhere between 60 and 120 min, depending upon the time available for the test and the final buildup. The final buildup is used to evaluate reservoir transmissibility, damage, and radius of investigation and should be at least as long as the final flow period. It is preferable (daylight permitting) to run the final build up three times as long as the final flow period to ensure that good pressure transient data is recorded.

Mud system

If a drill stem test is anticipated, low fluid loss mud will prevent excessive leakoff into the target zone and doping the mud with nitrates will distinguish filtrate from recovered formation water.

Test tools

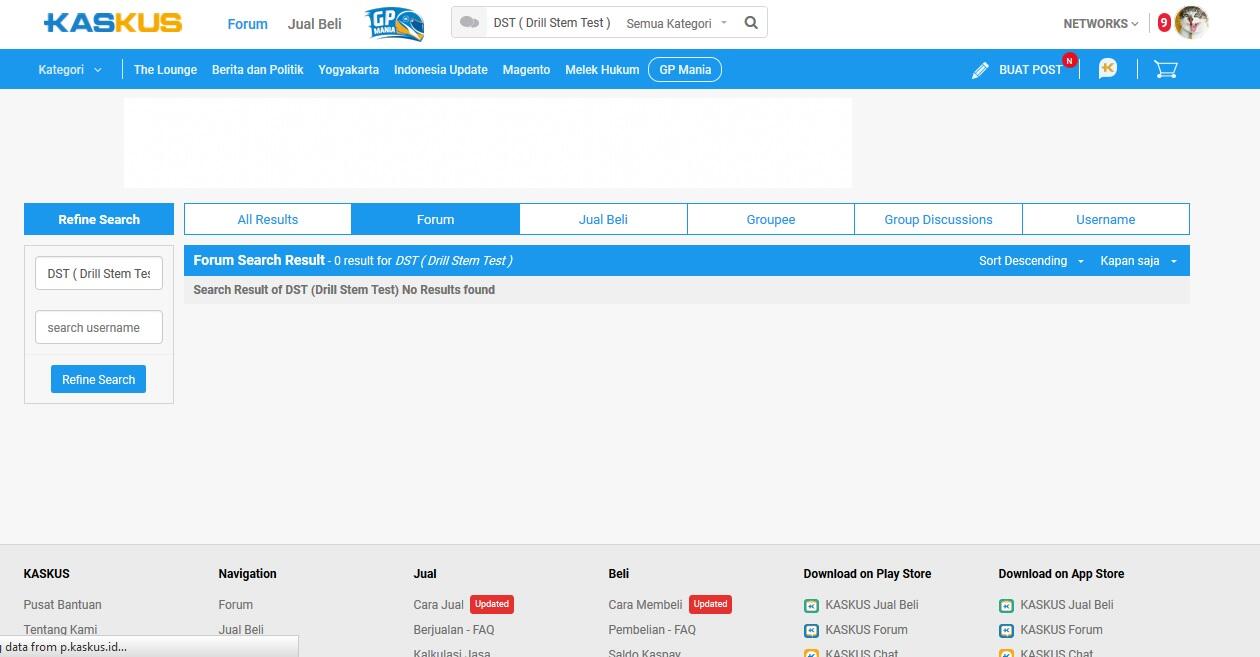

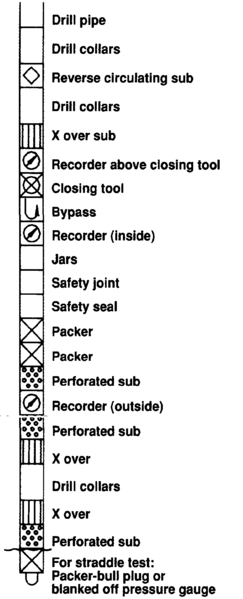

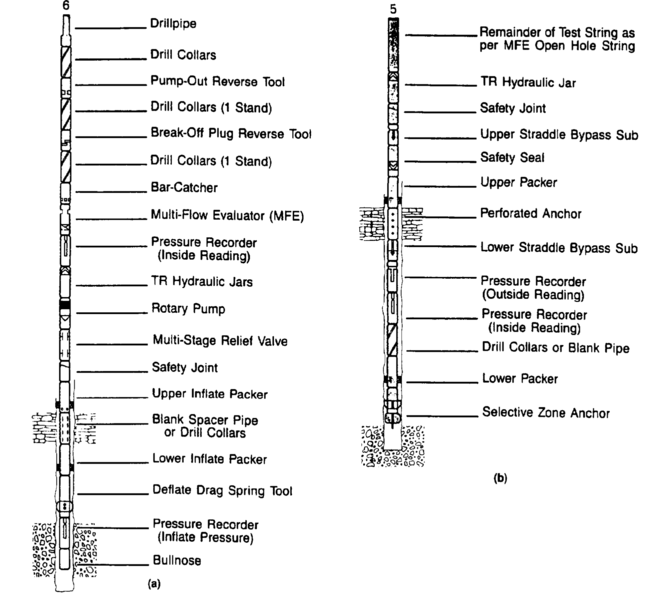

A drill stem test string consists of packers, a downhole shut-in valve, a safety joint, and pressure gauges (Figure 1). The bottom packer and blanked off gauge are shown as an “add on” to a straddle test.

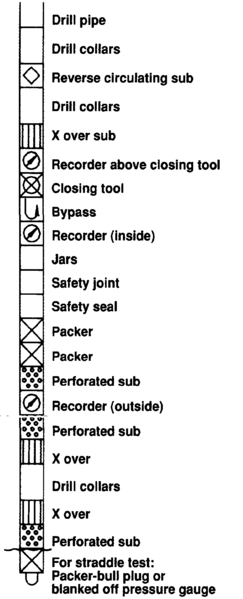

Figure 2 Straddle drill stem test tool string. (a) Typical MFE inflate open hole string (straddle, off-bottom). (b) Typical MFE straddle string (open hole, conventional, off-bottom). (From Flopetrol-Johnston[4].)

Packers

Compression set packers are generally more reliable than inflatable packers because they can withstand more differential pressure between the annulus and the drill string. The number of packers depend upon experience and test type (conventional, straddle, or hookwall.[5] Figure 2 illustrates other types of test strings.

Packer selection is also determined by the need for a cushion. A cushion consists of water or gas and is run for the following reasons:

Cushions also provide back pressure on the formation, which inhibits flow into the test string. If considerable damage or low permeability is expected, the cushion should be small.

Pressure gauges

A minimum of three (mechanical, electronic, or a combination) pressure and temperature recorders should be run on a conventional test and four on a straddle test. Selection depends on how accurate the data need to be.

One gauge should always be run inside the drill string above the closing tool. This gauge measures the hydrostatic head of fluid produced into the drill pipe and is critical to evaluating the volumes of fluids produced during the test. It also indicates drill string leakage during the test.

Two gauges should be run below the closing tool to measure pressure during the flow and shut-in periods. Two are needed to verify that they are reading within their calibration ranges and to provide a backup in case one fails.

A blanked off gauge must be run on a straddle test to verify that the bottom packers were holding. In most cases of straddle test failure, it is the bottom packers that fail.

Analyzing the DST

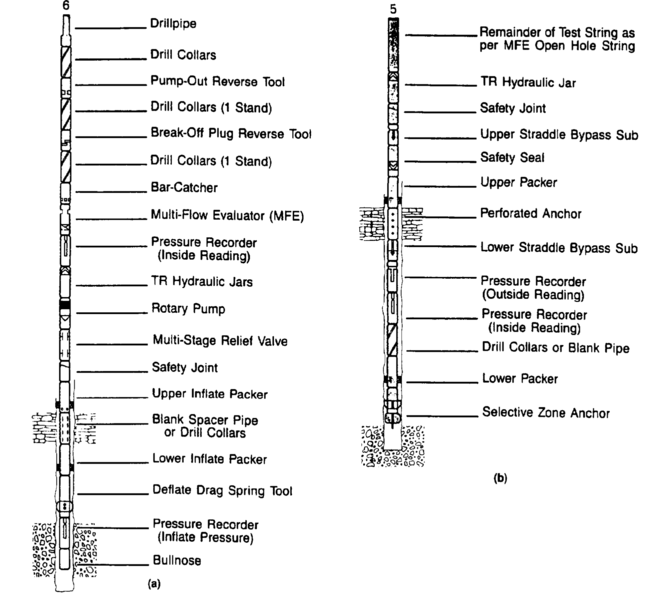

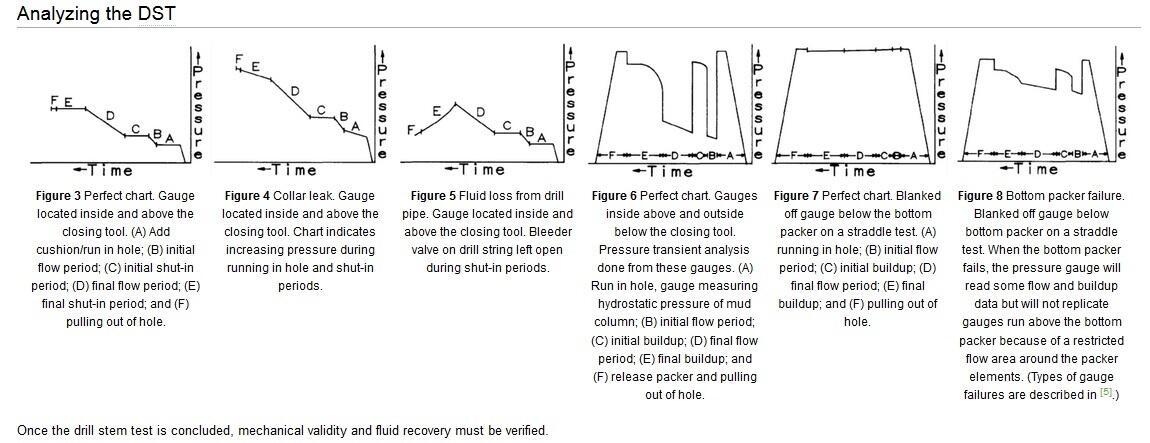

DST chart analysis

Descriptions of valid DST charts are shown in Figures 3, 4, 5, 6, 7, and 8.

Fluid recovery (Nonflowing Test)

On an NFDST, the volume of fluid produced from the formation is contained in the drill string. A fluid level must be determined to calculate the volume recovered. If the fluid is highly gas-cut, a straight volume calculation will be inaccurate. Therefore, samples should be collected at regular intervals while reversing to a clean tank on location. Although it is common to reverse to a pit, the amount of fluid recovered cannot be determined if this is done. Error in measuring fluid recovery often makes the difference between an economic disaster or a success. Also, grindouts (centrifuge) must be performed on each sample to determine the percentage of oil, water, and solids. Resistivity, chloride content, and nitrate content of produced water and the specific gravity of all phases should be measured.

Estimating flow rates (Nonflowing Test)

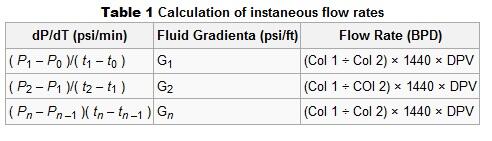

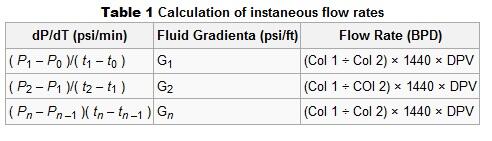

During the flow period on a DST, the flow rate is not constant. A flow rate can be calculated using pressure data from the gauge above the shut-in tool. By dividing the time scale into discrete increments and recording the pressure, the data can be transposed to a position in the drill pipe. Since the volume of the drill string and the changing fluid composition are known, instantaneous flow rates can be calculated as shown in Table 1.

Other methods include the following:

Interpretation

The most important parameters in DST interpretation are the radius of investigation (ROI) and the observed wellbore storage constant (WBSC). A short ROI, combined with knowledge of drilling fluid properties (fluid loss or amount of overbalance), may indicate that the calculated permeability is indicative of only the damaged zone. Usually, a skin factor close to zero is calculated under these conditions, along with a low formation transmissibility (kh/μ). One way to “see” past this damaged zone is to rerun the drill stem test with longer flow and shut-in periods.

If fractures are present, the measured WBSC may be much higher than the calculated WBSC. A high transmissibility and a negative skin will be computed under these conditions. A negative skin implies stimulation, which cannot occur during normal drilling operations. If an interval is fractured, recoveries and calculated flow rates can be much greater than expected future production.

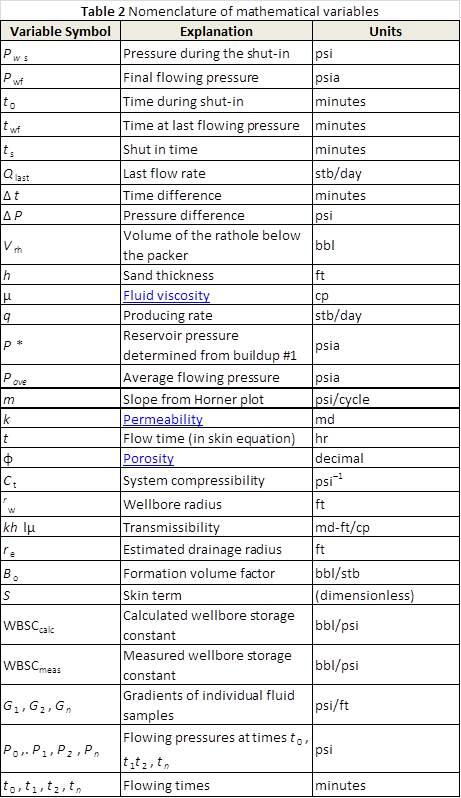

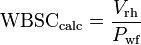

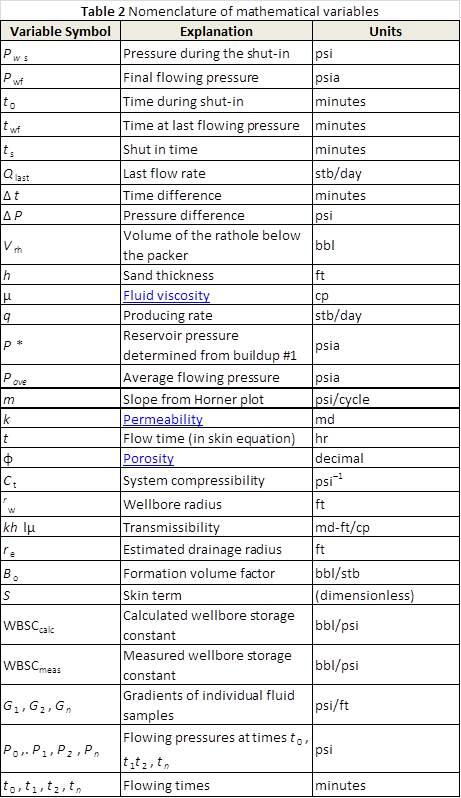

Calculating wellbore storage capacity

To calculate the wellbore storage capacity (WBSC), plot log (Pws – Pwf) versus log (ts – twf) (terms defined in Table 2). Because of storage effects, the early portion of the data will have a unit slope. As these effects diminish, data points on the log-log plot fall below the unit slope line and approach the slowly curving line for no wellbore storage. The measured WBSC (WBSCmeas) is calculated using one point from the unit slope line in the following equation:

(See Table 2 for explanation of mathematical variables.)

Table 2 Nomenclature of mathematical variables

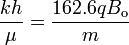

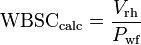

The calculated WBSC (WBSCcalc) is computed as follows:

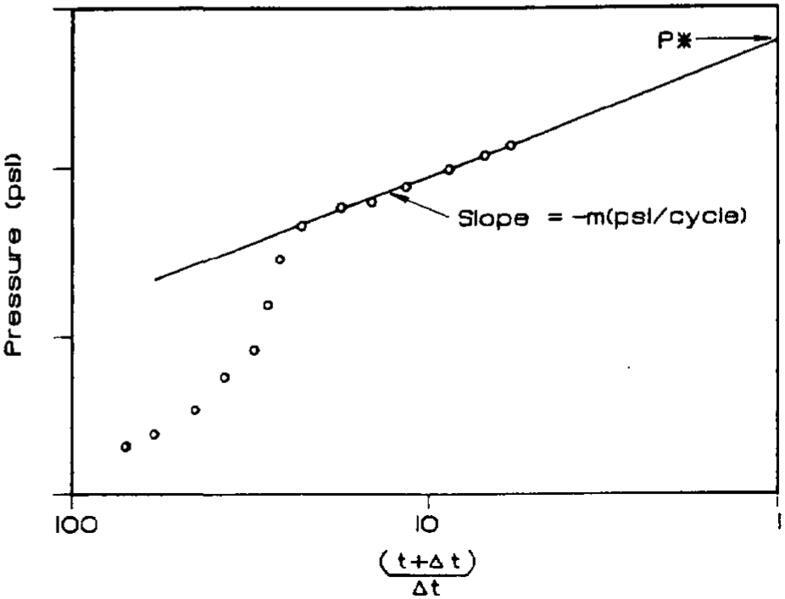

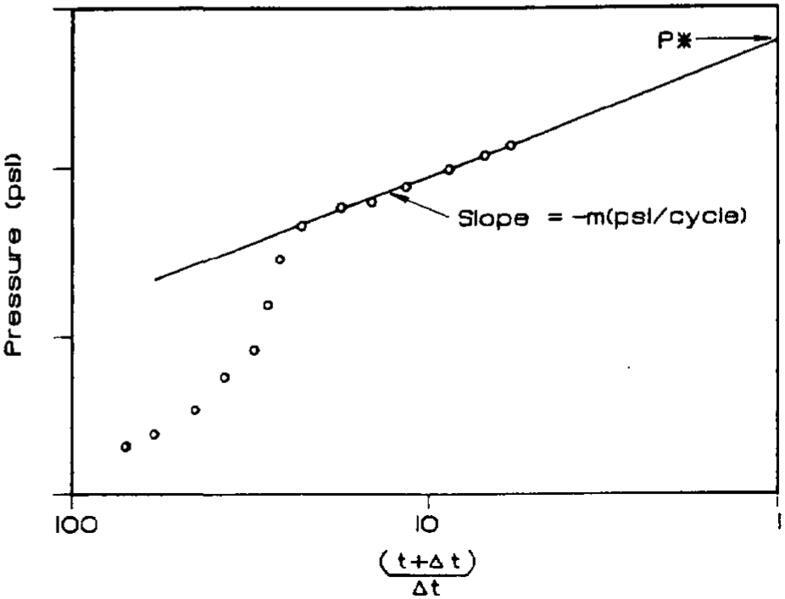

Calculating static reservoir pressure

Reservoir pressure (P*) is calculated by extrapolating the pressure data (from the first buildup on a DST) on the Horner (or superposition) plot to an infinite shut-in rime (Figure 9). This pressure provides a guide for selecting the slope of the second buildup Horner plot. If the second buildup slope extrapolates to a pressure significantly less than P*, depletion might be suspected. To see true depletion, the reservoir would have to be very small. Although depletion is possible in rare cases, identifying it is usually a result of poor test design and analysis.

A method for constructing the Horner plot is outlined as follows. After determining the effective producing time and producing rate, tabulate time and pressure for each buildup period. Make plots using Cartesian paper because this makes it easier to expand the plot (see Figure 9). Now plot P versus log[(t + Δt)/Δt] for buildup #1 (the first buildup following the first flow period). Note that t in this equation is equal to the length of the initial flow period and that Δt is the time since the start of the buildup period.

Extrapolate this curve to P* at log[(t + Δt)/Δt] = 0. P* provides the “guiding light” for determining the proper slope found using buildup #2. Now plot P versus log[(t + Δt)/Δt] for buildup #2. Note here that this t is the effective producing time calculated from one of the methods outlined earlier.

Extrapolate the straight-line portion of the data to P*. Use a data band within the accuracy of the gauge to make sure you choose the correct slope. In other words, if the gauge is accurate within ±5 psig, then the data band should be 10 psi wide on the graph. A data band is extremely important in cases where m m using two points: (x1, y1) and (x2, y2), where

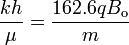

Now calculate the formation transmissibility as follows:

Note that k/μ can be calculated directly from the transmissibility term if the thickness, h, is known. Also, if a good value for μ is known, the formation capacity, kh, can be determined.

Calculating skin factor

The skin factor (S) can be calculated as follows:

If fluid properties are unavailable, skin can be calculated assuming that the log term in the previous equation is equal to 7.5. In most cases, the skin will either be positive or close to zero. A negative skin greater than –1 should be viewed with caution since the well has not been stimulated.

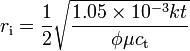

Calculating radius of investigation

The radius of investigation (ROD is important because it helps determine whether or not the test saw beyond wellbore damage. It is defined as

where t is the buildup time in hours and all other terms have been previously defined. The ROI calculated from a DST should not be used to identify faults or boundaries. If such items are in question, they should be determined through further transient testing.

Using the pseudo-steady-state radial flow equation, the potential of the tested interval can be estimated as follows:

Selain penjelasan diatas, masih banyak penjelasan DST in Petroleum Industry lainnya yang dapat digali informasinya lebih dalam gans,

Semoga bermanfaat

Thanks to penulis2 dan pengamat artikel2 ttg DST to share the knowledge

Harapan:

Berharap mendapatkan cendol dari kristalisasi keringat membuat thread ini…

Sumur:

Sharing Knowledge Gans,

DST (Drill Stem Test) in Petroleum Industry

Cekidot no repsol gan,

Norepsol:

Spoiler for No Repsol:

DST (Drill Stem Test) merupakan salah satu test dari berbagai macam test yang dilakukan dalam penyelesaian (Completion) sumur pemboran, biasanya dilakukan pada Sumur Explorasi Migas. Data tersebut sangat krusial dalam penentuan cadangan migas suatu lapangan migas.

Original Theory & Practices

Spoiler for DST:

Drill stem testing

Introduction

A drill stem test (DST) is a temporary completion of a wellbore that provides information on whether or not to complete the well. The zone in question is sealed off from the rest of the wellbore by packers, and the formations' pressure and fluids are measured. Data obtained from a DST include the following:

- fluid samples

- reservoir pressure (P*)

- formation properties, including permeability (k), skin (S), and radius of investigation (ri)

- productivity estimates, including flow rate (Q)

- hydrodynamic information

This article focuses on nonflowing DSTs (NFDSTs). In a NFDST, fluid does not flow to the surface and a stabilized flow rate is not obtained (also, the well can flow to the surface but die or be shut-in before steady-state rates are achieved). Analysis of flowing DSTs is less complicated because flow rates can be measured throughout the test

Planning

The key to successful testing depends upon planning and teamwork between the geoscientist and the engineer. Potential pay zones should be identified before drilling commences so that the drilling program can be designed to accommodate the test. If offset data are available, the magnitude of porosity, permeability, and reservoir pressure should be identified. Knowledge of zonal mineralogy may prevent excessive damage by drilling fluids and should be used in designing the mud program. The anticipated reservoir properties are used to design the test string and test times so that the best, most useable data can be obtained.

Safety

Running a DST is one of the most dangerous jobs in the oil field because the well is essentially uncontrolled during the test. All fire fighting equipment and the blowout preventers should be inspected and tested before starting a DST. Hydrogen sulfide (H2S) equipment should be on hand if anticipated conditions are sour. No test should be initiated at night or during an electrical storm. No smoking should be allowed on the drill floor or near any flowlines or surface test equipment.

Packer seats

The best time to run a DST is just after drilling through a potential pay zone, when exposure to damaging fluids is minimal and the hole is in its best condition for a good packer seat. Packer seats are generally located in competent sandstones or carbonates above the test interval or both above and below it. The packer seat is picked by the geoscientist or mudlogger using cuttings and the rate of penetration (ROP) as guides. Soft formations, characterized by a fast ROP, usually do not make good packer seats because the packer has trouble seating or gripping the side of the borehole. This results in poor pressure seals, or in extreme cases, the packer may slide down the hole.

Length of test interval

The length of the test interval should be short so that less mud will be displaced from the rathole (the portion of the open hole below the bottom packer) into the drill string.

Length of test time

The length of flow and shut-in periods during the test are critical to obtaining good reservoir data. The dual flow, dual shut-in test is most commonly used. The initial flow period of 3-5 min removes the “supercharge” effect of mud filtrate near wellbore. The first buildup is run for 60 min to determine a valid P* (reservoir pressure). The second flow period is used to collect a fluid sample and create a pressure disturbance at a distance beyond any damaged zone. The duration of the final flow period may be anywhere between 60 and 120 min, depending upon the time available for the test and the final buildup. The final buildup is used to evaluate reservoir transmissibility, damage, and radius of investigation and should be at least as long as the final flow period. It is preferable (daylight permitting) to run the final build up three times as long as the final flow period to ensure that good pressure transient data is recorded.

Mud system

If a drill stem test is anticipated, low fluid loss mud will prevent excessive leakoff into the target zone and doping the mud with nitrates will distinguish filtrate from recovered formation water.

Spoiler for DTS Tool string:

Test tools

A drill stem test string consists of packers, a downhole shut-in valve, a safety joint, and pressure gauges (Figure 1). The bottom packer and blanked off gauge are shown as an “add on” to a straddle test.

Figure 2 Straddle drill stem test tool string. (a) Typical MFE inflate open hole string (straddle, off-bottom). (b) Typical MFE straddle string (open hole, conventional, off-bottom). (From Flopetrol-Johnston[4].)

Packers

Compression set packers are generally more reliable than inflatable packers because they can withstand more differential pressure between the annulus and the drill string. The number of packers depend upon experience and test type (conventional, straddle, or hookwall.[5] Figure 2 illustrates other types of test strings.

Packer selection is also determined by the need for a cushion. A cushion consists of water or gas and is run for the following reasons:

- To prevent drill string collapse during deep tests or when high mud weights are used

- To prevent excessive differential pressure across the packer(s) during the flow periods

- To prevent high differential pressure across the sand face in unconsolidated formations, which will result in sand flow

- To prevent corrosion of the drill string from corrosive gases such as H2S or CO2

Cushions also provide back pressure on the formation, which inhibits flow into the test string. If considerable damage or low permeability is expected, the cushion should be small.

Pressure gauges

A minimum of three (mechanical, electronic, or a combination) pressure and temperature recorders should be run on a conventional test and four on a straddle test. Selection depends on how accurate the data need to be.

One gauge should always be run inside the drill string above the closing tool. This gauge measures the hydrostatic head of fluid produced into the drill pipe and is critical to evaluating the volumes of fluids produced during the test. It also indicates drill string leakage during the test.

Two gauges should be run below the closing tool to measure pressure during the flow and shut-in periods. Two are needed to verify that they are reading within their calibration ranges and to provide a backup in case one fails.

A blanked off gauge must be run on a straddle test to verify that the bottom packers were holding. In most cases of straddle test failure, it is the bottom packers that fail.

Spoiler for Another DST Tool string:

Analyzing the DST

DST chart analysis

Descriptions of valid DST charts are shown in Figures 3, 4, 5, 6, 7, and 8.

Spoiler for Analysis Chart:

Fluid recovery (Nonflowing Test)

On an NFDST, the volume of fluid produced from the formation is contained in the drill string. A fluid level must be determined to calculate the volume recovered. If the fluid is highly gas-cut, a straight volume calculation will be inaccurate. Therefore, samples should be collected at regular intervals while reversing to a clean tank on location. Although it is common to reverse to a pit, the amount of fluid recovered cannot be determined if this is done. Error in measuring fluid recovery often makes the difference between an economic disaster or a success. Also, grindouts (centrifuge) must be performed on each sample to determine the percentage of oil, water, and solids. Resistivity, chloride content, and nitrate content of produced water and the specific gravity of all phases should be measured.

Estimating flow rates (Nonflowing Test)

During the flow period on a DST, the flow rate is not constant. A flow rate can be calculated using pressure data from the gauge above the shut-in tool. By dividing the time scale into discrete increments and recording the pressure, the data can be transposed to a position in the drill pipe. Since the volume of the drill string and the changing fluid composition are known, instantaneous flow rates can be calculated as shown in Table 1.

Spoiler for Tabel 1:

Other methods include the following:

- Superposition uses the rate schedule in analyzing the pressure data. The technique is described in Earlougher[1] and in Matthews and Russell.[3]

- The Odeh-Selig method (modified superposition) is fairly rigorous.[6] It is only valid if the shut-in period is 1.5 times greater than the flowing period.

- The modified Horner method uses effective flow time and a flow rate calculated from the end of the second flow period. The effective flow time is calculated by dividing the total fluid recovery in barrels by the flow rate in barrels per minute, which is then converted to barrels per day.

- The simplified Horner method converts total recovery and the flow time of the test to an average daily rate. The flow time using this method is the time the tool was open. Although this method is commonly used, it is incorrect to assume that this rate reflects stabilized producing rates. This method should only be used as a last resort.

Interpretation

The most important parameters in DST interpretation are the radius of investigation (ROI) and the observed wellbore storage constant (WBSC). A short ROI, combined with knowledge of drilling fluid properties (fluid loss or amount of overbalance), may indicate that the calculated permeability is indicative of only the damaged zone. Usually, a skin factor close to zero is calculated under these conditions, along with a low formation transmissibility (kh/μ). One way to “see” past this damaged zone is to rerun the drill stem test with longer flow and shut-in periods.

If fractures are present, the measured WBSC may be much higher than the calculated WBSC. A high transmissibility and a negative skin will be computed under these conditions. A negative skin implies stimulation, which cannot occur during normal drilling operations. If an interval is fractured, recoveries and calculated flow rates can be much greater than expected future production.

Calculating wellbore storage capacity

To calculate the wellbore storage capacity (WBSC), plot log (Pws – Pwf) versus log (ts – twf) (terms defined in Table 2). Because of storage effects, the early portion of the data will have a unit slope. As these effects diminish, data points on the log-log plot fall below the unit slope line and approach the slowly curving line for no wellbore storage. The measured WBSC (WBSCmeas) is calculated using one point from the unit slope line in the following equation:

Spoiler for Equation 1:

(See Table 2 for explanation of mathematical variables.)

Table 2 Nomenclature of mathematical variables

Spoiler for Table 2:

The calculated WBSC (WBSCcalc) is computed as follows:

Spoiler for Equation 2:

Calculating static reservoir pressure

Reservoir pressure (P*) is calculated by extrapolating the pressure data (from the first buildup on a DST) on the Horner (or superposition) plot to an infinite shut-in rime (Figure 9). This pressure provides a guide for selecting the slope of the second buildup Horner plot. If the second buildup slope extrapolates to a pressure significantly less than P*, depletion might be suspected. To see true depletion, the reservoir would have to be very small. Although depletion is possible in rare cases, identifying it is usually a result of poor test design and analysis.

A method for constructing the Horner plot is outlined as follows. After determining the effective producing time and producing rate, tabulate time and pressure for each buildup period. Make plots using Cartesian paper because this makes it easier to expand the plot (see Figure 9). Now plot P versus log[(t + Δt)/Δt] for buildup #1 (the first buildup following the first flow period). Note that t in this equation is equal to the length of the initial flow period and that Δt is the time since the start of the buildup period.

Extrapolate this curve to P* at log[(t + Δt)/Δt] = 0. P* provides the “guiding light” for determining the proper slope found using buildup #2. Now plot P versus log[(t + Δt)/Δt] for buildup #2. Note here that this t is the effective producing time calculated from one of the methods outlined earlier.

Extrapolate the straight-line portion of the data to P*. Use a data band within the accuracy of the gauge to make sure you choose the correct slope. In other words, if the gauge is accurate within ±5 psig, then the data band should be 10 psi wide on the graph. A data band is extremely important in cases where m m using two points: (x1, y1) and (x2, y2), where

Now calculate the formation transmissibility as follows:

Note that k/μ can be calculated directly from the transmissibility term if the thickness, h, is known. Also, if a good value for μ is known, the formation capacity, kh, can be determined.

Spoiler for Figure 9 Horner plot.:

Calculating skin factor

The skin factor (S) can be calculated as follows:

If fluid properties are unavailable, skin can be calculated assuming that the log term in the previous equation is equal to 7.5. In most cases, the skin will either be positive or close to zero. A negative skin greater than –1 should be viewed with caution since the well has not been stimulated.

Calculating radius of investigation

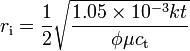

The radius of investigation (ROD is important because it helps determine whether or not the test saw beyond wellbore damage. It is defined as

where t is the buildup time in hours and all other terms have been previously defined. The ROI calculated from a DST should not be used to identify faults or boundaries. If such items are in question, they should be determined through further transient testing.

Using the pseudo-steady-state radial flow equation, the potential of the tested interval can be estimated as follows:

Selain penjelasan diatas, masih banyak penjelasan DST in Petroleum Industry lainnya yang dapat digali informasinya lebih dalam gans,

Semoga bermanfaat

Thanks to penulis2 dan pengamat artikel2 ttg DST to share the knowledge

Harapan:

Spoiler for Harapan:

Berharap mendapatkan cendol dari kristalisasi keringat membuat thread ini…

Sumur:

Spoiler for Sumur:

0

3.1K

Kutip

4

Balasan

Komentar yang asik ya

Urutan

Terbaru

Terlama

Komentar yang asik ya

Komunitas Pilihan