TS

boleroes11

System for the crews of armored combat vehicle (part 1).

System for the crews of armored combat vehicles (part 1)

Today, 9:08 Print

Suspended dynamic seats allow you to adjust the position of the driver, as well as crew members in the tower of heavy combat vehicles

Despite the fact that the modern battle focused on the dismounted soldier crews cars also pay more attention to improve their gear and equipment that will allow them to operate more effectively in combat conditions, increase the "comfort" (ie, decrease fatigue and increase efficiency) integrates each crew member in a network-centric space and, most importantly, to protect the crew from improvised explosive devices (IEDs). At the same time protecting the crew from the shock wave vibration, ambient temperature, load of dust and other harmful factors, the system itself must be able to function under such conditions.

Seats, reducing the impact of the blast wave

During a combat mission, as a rule, most of the time the crew car sits. Accordingly, the seats that they use affect factors such as fatigue and vitality. In response to the threat posed by mines and improvised explosive devices, the need to protect the crew sitting growing exponentially. Many, if not most of the injuries that occur when exposed to vertical or horizontal blast wave on the armored car or strategic, is not due to armor penetration. Since damage usually occur from exposure to shock waves, the design of many obsolete seats may actually amplify the power of human exposure to almost five times. Indeed, the non-conforming seat and internal fixation often themselves become the cause of death or injury of personnel than the blast itself. One of the most common injuries of the crew is the destruction of the spine, when he instantly compressed under tremendous pressure so that his vertebrae collapse and split into pieces.

The U.S. Army has identified five major threats resulting in losses: head-on collisions, collisions in pursuit in the back of the machine, side impact machines and IEDs. Another factor to be taken into account for additional armored vehicles such as MRAP and HMMWV, is that their center of gravity is raised because of the V-shaped bottom of mine and while maneuvering to evade the collision there is an increased risk of rollover which is fraught with fatal outcome, especially when you turn the machine off bridges or roadsides.

Based on the substance of the threat from the placement of seats inside the armored armored vehicles can be a little disconcerting. Rather, specially designed seats, called protected seats, explosion-proof seats, seats or Ex finally antitravmaticheskimi seats designed for personnel in the car survived the high acceleration, which creates a detonation of explosives near the car or under it. The emphasis is on the prevention of the shock wave on the human inside the, or at least its attenuation. Explosion underneath usually causes instant, temporary plastic deformation of the bottom. For this reason the explosion-seat sides are usually fixed to the housing and not to the bottom and ideally equipped footrests for the feet to separate completely from the bottom of the soldier. Another requirement - a powerful system of fixing sitting, which could prevent it from moving in the blast.

It should be understood, however, that the flameproof seats are part of the entire machine and can not be separated from it. Each type of machine will respond to different burst is determined primarily by such characteristics as overall vehicle weight, weight distribution within the machine, the bottom profile of the type of system installed and protection. As a result, each combination of machines, weights and protection during an attack will give your special impulse (acceleration and its duration) who have experienced sitting inside. Thus, at the same power with a heavy machine explosion protected well V-bottom shaped transmit pulse is smaller as compared with a light machine with a flat bottom and weak protection.

Consequently, it follows that it is necessary to "adjust" the energy attenuation system for the platform in order to guarantee the survival of the passengers and crew. It should also be noted that the energy absorbing system suitable for one platform, e.g., a 30-ton vehicle can not give the MRAP considerable protection for lighter trucks with a flat bottom. And, no matter what system reduce energy blast wave set, if the mechanism of attack delivers much higher energy than the one on which it was designed seat, it does not fulfill its purpose and sitting on it will get problems.

Following is a brief presentation of some typical models Ex models, which in the vast variety of currently available on the market.

The technology, called Dynamic Seats System (Dynamic Seat System), goes back to work in the field of Autoflug parachute technology, but in this case it is aimed at reducing the impact forces that occur when a landmine or IED. The system consists of a safety-belt system, connected to the body by six and one limiter stops Zero-G soldier for holding in place the case of overturning. Sitting position is controlled by mechanical springs and Bowden cable through the control unit and the weight of sitting becomes the driving force. Electronics and hydraulics design not used.

While in traditional seats, Mounted to the bottom of the body or used shock-absorbing system or other mitigating system in order to prevent the transmission of forces on the spine and internal organs, the company has created Autoflug rest on the principle of parachute, with fastening to the ceiling, while avoiding the hard metal ties. The laws of physics tell us that the compressive force can not be transmitted through the fabric, so you can not push on a rope (theoretically).

This seating system has been implemented in a large number of programs around the world, including six national operators tanks LEOPARD 2 in Europe and the United States, these seats installed on their tanks ABRAMS M1A1 and M1A2 SEP.

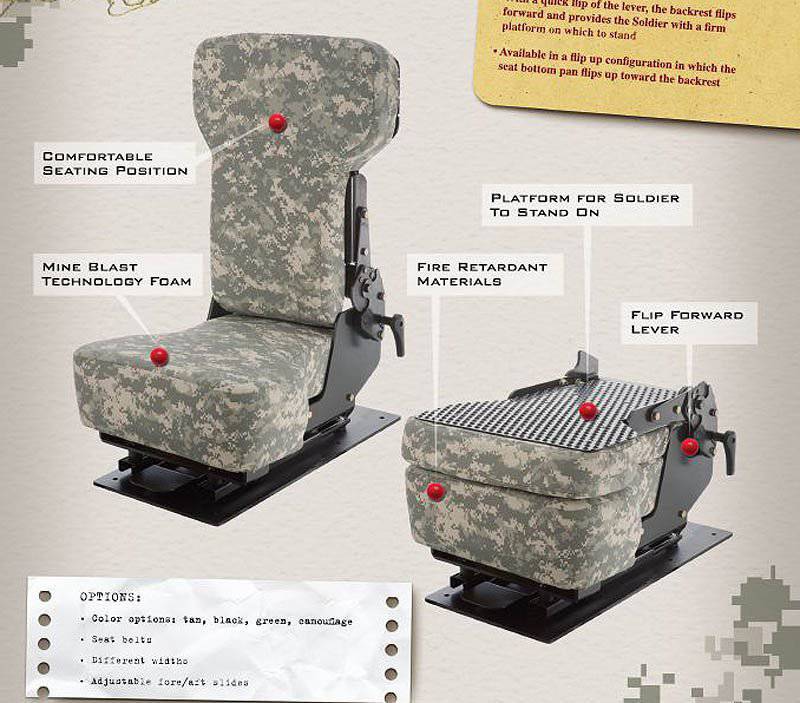

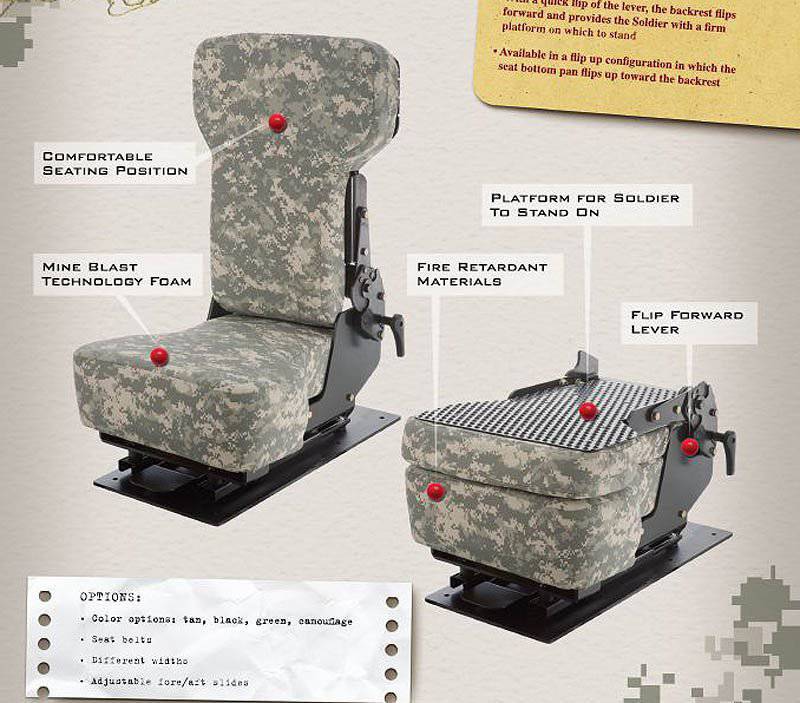

Global Seating Systems Company established its family CCOPS (Common Crash worthy Occupant Protection System - common system of protection of personnel in the event of an accident) or «See-Cops», which includes seat systems COBRA, VIPER, SIDEWINDER and DIAMONDBACK. Each system performs a specific task; eg DIAMONDBACK back folds down, allowing the arrow to get up on the seat when doing the shooting. Seat of GSS has been installed on a number of American cars MRAP.

The British company Creation recently revealed the details of a new explosion-proof test seat. The company worked on it together with your partner Universal Engineering for installation in a secure car RANGER. The new seat is in the form of a ladle, it used technology taken from medical and osteopathic orthopedic chairs. Seat frame is not fixed to the bottom and to the sides of the machine. This, as shown by the test, allows you to control the upward acceleration, and thus weaken the powerful impact. This is done by two vertical pipes suspended on supports linear bearings. In order to reduce the force of impact was equipped with two hydraulic telescopic damper and other components. Sitting strapped by a set of four-point seat belts Securon.

Seat DIAMONDBACK

Countermines seat personnel (Mine Blast Utility Troop Seat) from the company BAE Systems can be installed in a variety of positions, namely face forward, sideways or backwards, it can be attached to the bulkhead to the board or just be a frame structure. This allows you to install this seat on a wide range of machines. The main seat design includes a tubular frame with fabric seat and back, the energy absorption system, four-point locking system, plus an additional removable headrest, retractable click, contoured support for the thighs, explosion-proof bowl seat and adjustable backrest.

The family seat from BLASTech Jankel used seat technology and limiting the debilitating shock wave that has already been tested in combat conditions. Seats created in order to ensure survival in the main pulse with a peak acceleration of 2,000 G of more than 2 milliseconds. Seats tested on machines to the levels stated in the standard STANAG 4569, in accordance with the strict requirements of NATO AEP-55 VOL 2. Footrest Footpad - J-Pad (Jankel Pulse Attenuation Device - reducing device pulse from Jankel) designed to enhance the protection of drumsticks and foot soldiers. Support Design optimized so that only provides for the destruction of such loads close to the peak, which are permitted for the lower leg. Automatic adjustment of the mass determines compensatory seats for seated resistance in the range from the 5th to the 95th percentile, which makes it possible to adjust the seat to the soldier under his weight with a lever attached to the seat. Restart function defines a second attenuation range applicable for secondary event called "throwing down." At a time when a soldier has no weight, power attenuation overloaded secondary event when the machine "throws down."

Thermal load can have a dramatic impact on performance of a soldier in the field. Scientific studies clearly show that the temperature rise of the body, the performance degrades. Cooling plant GORE Active Cooling Products up to 150 watts of companies Gore excellent distribute refrigerant under pressure. They are flexible and comfortable portable solution to reduce the heat load on the dismounted soldier

Absorber seat SHOCKRIDE from ArmorWork

In the new intrinsically safe seats from QinetiQ North America uses an innovative damping system to mitigate the impact of mines and IEDs; it can protect the crew and landing vehicles of various types

ArmorWorks company is considered the industry leader in the development of energy-absorbing protective systems. The Company uses its know-how in the development of energy-absorbing seats to protect soldiers from the destructive impact of the blast wave.

Founded in 1996, the company is a leading supplier ArmorWorks for military and law enforcement agencies around the world advanced products that improve survivability. ArmorWorks develops and manufactures advanced products in the field of protecting and enhancing the survivability of using high-tech materials to provide real protection level. Division SHOCKRIDE developed energy-absorbing seat system, which the U.S. government tested and approved to increase the protection of personnel undergoing landmine.

In the new intrinsically safe seats on the company QinetiQ North America uses an innovative damping system to reduce the impact of mines and IEDs, it is able to protect soldiers in most cars of various models. Blasting and laboratory tests have shown that mitigation technology used in these seats can reduce the burden attributable to the spine and pelvis of a soldier from 1800 to 20G (load level, guaranteeing survival). In addition, the seats are designed ergonomically to ensure comfort when driving, and their features are planning loads and rapid evacuation of seats.

Cooling

There was a time when it was believed that the presence of air conditioning in the military machine has a negative impact on the image of the "macho soldier." The U.S. Army, for example, buying a standard commercial trucks, paying extra money for the removal of air conditioners. But summer temperatures inside vehicles in Afghanistan (and earlier in Iraq) reach over 50 ° C, and the cooling system is no longer considered as something unnecessary, but rather an integral part of the equipment for a combat mission. They are designed not so much to enhance the comfort of the crew as to maintain the temperature at which it would not have received from heat stroke during combat operations. Plus, of course, the need to prevent overheating of the growing number of important on-board electronics. While the system for the crew may alleviate the problem, they are just part of a comprehensive strategy to reduce the temperature. Cooling module must also provide a small amount, size and weight, low energy consumption, since cars have become overloaded with additional armor and fire protection systems and fire.

Cooling Systems crews used as an integral part of the integrated systems of protection against weapons of mass destruction in machines that can be sealed, and as a separate component of an integrated system of protection against weapons of mass destruction in the machines, which can be sealed, or, finally, as individual solutions for machines that do not have this option, as well as part of a conventional heating systems, ventilation and air conditioning (HVAC).

Bioquell company uses the usual cycle of evaporation cooling systems in their power 5-9 kW. The system consists of an evaporator, a compressor directly connected to the main engine, a condenser outlet flow 3.2 m3 / s, the control unit, corresponding to refrigerant hoses and wiring harnesses. The cooled air is directed to the individual crew stations to maximize cooling. The system weighs about 45 kg and has dimensions of 590x380x302 mm.

South African company Booyco Engineering has developed solutions for the control of environmental conditions, including cooling and auxiliary power units for a variety of platforms, from attack helicopters to ROOIVALK corvettes. Development of the system were used in climate control crew LCCCS (Crew Climate Control System) tank LEOPARD. This module is designed for Australia and is set in a bustle MBT LEOPARD, as well as machines for minozaschischennyh RG-31 and 155-mm self-propelled howitzers wheeled G6. RG31 system was developed at the direction of the company BAE Systems and was delivered in 2009. A system using ready made components installed under the rear seats, and uses one common filter for air recirculation and fresh air. At the trials unit issued cooling capacity of 8 kW at an ambient temperature of 55 ° C.

Trucks also require cooling. Company Red Dot Corp eg HVAC supplies modules for the family of military vehicles, medium-duty FMTV (Family of Medium Tactical Vehicles) U.S. Army.

Instead of cooling air in some wearable systems to reduce body temperature circulates chilled water. They have some advantages such as reducing the size, weight and power consumption as compared with systems HVAC, some estimates suggest that savings can reach 70%. Wearable systems also allow you to work effectively with open hatches machine or crewmember position "for sea."

One of the solutions in the field of cooling systems and equipment crew, designated ICECS (individual crew and equipment cooling systems), was developed by an Israeli company Kinetics for MBT MERKAVA 3 and 4, this system were installed in 1997. Individual cooling vests created by the air-cooled. The system has since been adopted by other countries and is currently installed on a number of platforms, including missile launchers HIMARS, self-propelled howitzer M109A6 PALADIN, as well as various types of machines MRAP.

Kinetics company manufactures three wearable systems: normal / air cooled fireproof overalls Regular / Fire Resistant Air-Cooled Overall), air-cooled overalls with NBC (NBC Protected Air-Cooled Overall) and compact air-cooled vest (Air-Cooled Compact Vest), which is designed to be worn under normal clothing or jacket.

As part of Air Warrior, last year the company received Cobham program individual cooling of the U.S. Army $ 110 million to equip the personnel of Army Aviation. The system is the first with a microclimate cooling system, which uses the method of cooling the circulating pressure system is also designed to be installed on ground vehicles. As for the personnel on board the aircraft, it was determined that the duration of the task may be safely extended to three hours or more.

The U.S. Army requested the QinetiQ's put it microclimate cooling subsystem for installation on ground systems after qualifying her for helicopters UH-60, CH-47D and OH-58D. It will install on the car and armored HMMWV digger M9, whose office for one person is very close to the motor car, which leads to very high temperatures. The system provides a cooling capacity of 324 W at an ambient temperature of 51 ° C, its mass is 58 kg.

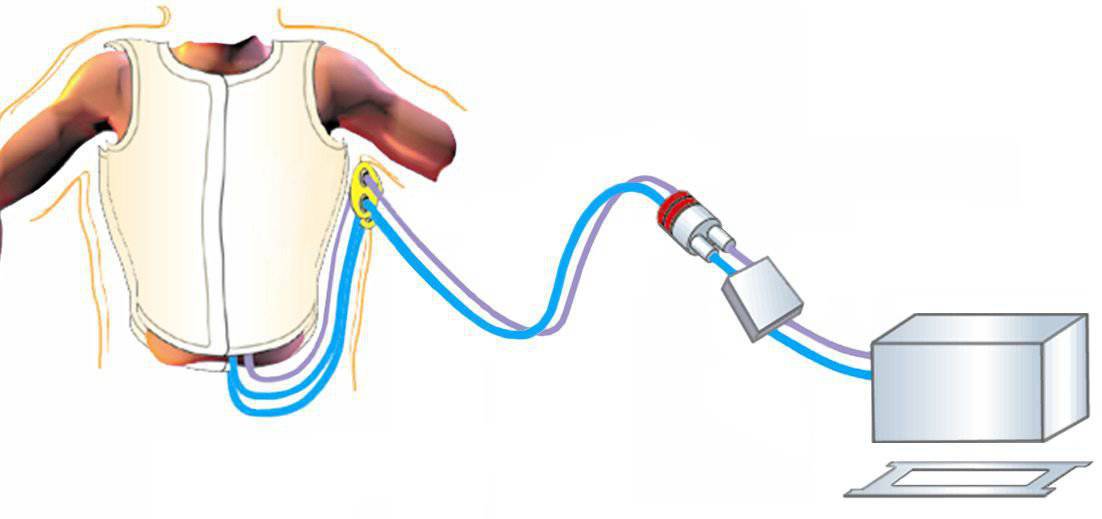

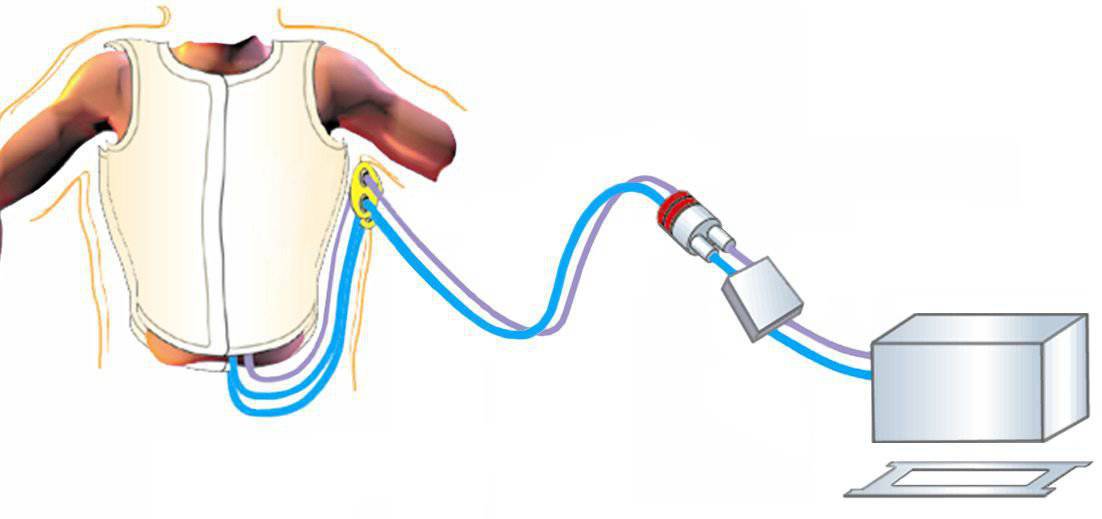

In February, the company WL Gore & Associates (UK) Ltd. active cooling system launched GORE. It is worn system created to meet the thermal standards, including British DefStd 00-35 (climate A1, A2, A3 & B2). Worn as a vest, the system provides cooling of the body directly, and works in conjunction with body armor, it is connected via a hose to the machine's cooling system. Insulation systems and sealed, and designed so that it can easily be removed in case of emergency.

Microclimate cooling system used for personal cooling and reduce thermal effects on individuals exposed to high temperatures or wearing clothing that holds heat. Microclimate cooling system - liquid (water glyukolevaya fluid as a coolant) and consists of a set in the car cooling unit worn under the outerwear cooling vest and connecting tubes with integrated control device

Today, 9:08 Print

Suspended dynamic seats allow you to adjust the position of the driver, as well as crew members in the tower of heavy combat vehicles

Despite the fact that the modern battle focused on the dismounted soldier crews cars also pay more attention to improve their gear and equipment that will allow them to operate more effectively in combat conditions, increase the "comfort" (ie, decrease fatigue and increase efficiency) integrates each crew member in a network-centric space and, most importantly, to protect the crew from improvised explosive devices (IEDs). At the same time protecting the crew from the shock wave vibration, ambient temperature, load of dust and other harmful factors, the system itself must be able to function under such conditions.

Seats, reducing the impact of the blast wave

During a combat mission, as a rule, most of the time the crew car sits. Accordingly, the seats that they use affect factors such as fatigue and vitality. In response to the threat posed by mines and improvised explosive devices, the need to protect the crew sitting growing exponentially. Many, if not most of the injuries that occur when exposed to vertical or horizontal blast wave on the armored car or strategic, is not due to armor penetration. Since damage usually occur from exposure to shock waves, the design of many obsolete seats may actually amplify the power of human exposure to almost five times. Indeed, the non-conforming seat and internal fixation often themselves become the cause of death or injury of personnel than the blast itself. One of the most common injuries of the crew is the destruction of the spine, when he instantly compressed under tremendous pressure so that his vertebrae collapse and split into pieces.

The U.S. Army has identified five major threats resulting in losses: head-on collisions, collisions in pursuit in the back of the machine, side impact machines and IEDs. Another factor to be taken into account for additional armored vehicles such as MRAP and HMMWV, is that their center of gravity is raised because of the V-shaped bottom of mine and while maneuvering to evade the collision there is an increased risk of rollover which is fraught with fatal outcome, especially when you turn the machine off bridges or roadsides.

Based on the substance of the threat from the placement of seats inside the armored armored vehicles can be a little disconcerting. Rather, specially designed seats, called protected seats, explosion-proof seats, seats or Ex finally antitravmaticheskimi seats designed for personnel in the car survived the high acceleration, which creates a detonation of explosives near the car or under it. The emphasis is on the prevention of the shock wave on the human inside the, or at least its attenuation. Explosion underneath usually causes instant, temporary plastic deformation of the bottom. For this reason the explosion-seat sides are usually fixed to the housing and not to the bottom and ideally equipped footrests for the feet to separate completely from the bottom of the soldier. Another requirement - a powerful system of fixing sitting, which could prevent it from moving in the blast.

It should be understood, however, that the flameproof seats are part of the entire machine and can not be separated from it. Each type of machine will respond to different burst is determined primarily by such characteristics as overall vehicle weight, weight distribution within the machine, the bottom profile of the type of system installed and protection. As a result, each combination of machines, weights and protection during an attack will give your special impulse (acceleration and its duration) who have experienced sitting inside. Thus, at the same power with a heavy machine explosion protected well V-bottom shaped transmit pulse is smaller as compared with a light machine with a flat bottom and weak protection.

Consequently, it follows that it is necessary to "adjust" the energy attenuation system for the platform in order to guarantee the survival of the passengers and crew. It should also be noted that the energy absorbing system suitable for one platform, e.g., a 30-ton vehicle can not give the MRAP considerable protection for lighter trucks with a flat bottom. And, no matter what system reduce energy blast wave set, if the mechanism of attack delivers much higher energy than the one on which it was designed seat, it does not fulfill its purpose and sitting on it will get problems.

Following is a brief presentation of some typical models Ex models, which in the vast variety of currently available on the market.

The technology, called Dynamic Seats System (Dynamic Seat System), goes back to work in the field of Autoflug parachute technology, but in this case it is aimed at reducing the impact forces that occur when a landmine or IED. The system consists of a safety-belt system, connected to the body by six and one limiter stops Zero-G soldier for holding in place the case of overturning. Sitting position is controlled by mechanical springs and Bowden cable through the control unit and the weight of sitting becomes the driving force. Electronics and hydraulics design not used.

While in traditional seats, Mounted to the bottom of the body or used shock-absorbing system or other mitigating system in order to prevent the transmission of forces on the spine and internal organs, the company has created Autoflug rest on the principle of parachute, with fastening to the ceiling, while avoiding the hard metal ties. The laws of physics tell us that the compressive force can not be transmitted through the fabric, so you can not push on a rope (theoretically).

This seating system has been implemented in a large number of programs around the world, including six national operators tanks LEOPARD 2 in Europe and the United States, these seats installed on their tanks ABRAMS M1A1 and M1A2 SEP.

Global Seating Systems Company established its family CCOPS (Common Crash worthy Occupant Protection System - common system of protection of personnel in the event of an accident) or «See-Cops», which includes seat systems COBRA, VIPER, SIDEWINDER and DIAMONDBACK. Each system performs a specific task; eg DIAMONDBACK back folds down, allowing the arrow to get up on the seat when doing the shooting. Seat of GSS has been installed on a number of American cars MRAP.

The British company Creation recently revealed the details of a new explosion-proof test seat. The company worked on it together with your partner Universal Engineering for installation in a secure car RANGER. The new seat is in the form of a ladle, it used technology taken from medical and osteopathic orthopedic chairs. Seat frame is not fixed to the bottom and to the sides of the machine. This, as shown by the test, allows you to control the upward acceleration, and thus weaken the powerful impact. This is done by two vertical pipes suspended on supports linear bearings. In order to reduce the force of impact was equipped with two hydraulic telescopic damper and other components. Sitting strapped by a set of four-point seat belts Securon.

Seat DIAMONDBACK

Countermines seat personnel (Mine Blast Utility Troop Seat) from the company BAE Systems can be installed in a variety of positions, namely face forward, sideways or backwards, it can be attached to the bulkhead to the board or just be a frame structure. This allows you to install this seat on a wide range of machines. The main seat design includes a tubular frame with fabric seat and back, the energy absorption system, four-point locking system, plus an additional removable headrest, retractable click, contoured support for the thighs, explosion-proof bowl seat and adjustable backrest.

The family seat from BLASTech Jankel used seat technology and limiting the debilitating shock wave that has already been tested in combat conditions. Seats created in order to ensure survival in the main pulse with a peak acceleration of 2,000 G of more than 2 milliseconds. Seats tested on machines to the levels stated in the standard STANAG 4569, in accordance with the strict requirements of NATO AEP-55 VOL 2. Footrest Footpad - J-Pad (Jankel Pulse Attenuation Device - reducing device pulse from Jankel) designed to enhance the protection of drumsticks and foot soldiers. Support Design optimized so that only provides for the destruction of such loads close to the peak, which are permitted for the lower leg. Automatic adjustment of the mass determines compensatory seats for seated resistance in the range from the 5th to the 95th percentile, which makes it possible to adjust the seat to the soldier under his weight with a lever attached to the seat. Restart function defines a second attenuation range applicable for secondary event called "throwing down." At a time when a soldier has no weight, power attenuation overloaded secondary event when the machine "throws down."

Thermal load can have a dramatic impact on performance of a soldier in the field. Scientific studies clearly show that the temperature rise of the body, the performance degrades. Cooling plant GORE Active Cooling Products up to 150 watts of companies Gore excellent distribute refrigerant under pressure. They are flexible and comfortable portable solution to reduce the heat load on the dismounted soldier

Absorber seat SHOCKRIDE from ArmorWork

In the new intrinsically safe seats from QinetiQ North America uses an innovative damping system to mitigate the impact of mines and IEDs; it can protect the crew and landing vehicles of various types

ArmorWorks company is considered the industry leader in the development of energy-absorbing protective systems. The Company uses its know-how in the development of energy-absorbing seats to protect soldiers from the destructive impact of the blast wave.

Founded in 1996, the company is a leading supplier ArmorWorks for military and law enforcement agencies around the world advanced products that improve survivability. ArmorWorks develops and manufactures advanced products in the field of protecting and enhancing the survivability of using high-tech materials to provide real protection level. Division SHOCKRIDE developed energy-absorbing seat system, which the U.S. government tested and approved to increase the protection of personnel undergoing landmine.

In the new intrinsically safe seats on the company QinetiQ North America uses an innovative damping system to reduce the impact of mines and IEDs, it is able to protect soldiers in most cars of various models. Blasting and laboratory tests have shown that mitigation technology used in these seats can reduce the burden attributable to the spine and pelvis of a soldier from 1800 to 20G (load level, guaranteeing survival). In addition, the seats are designed ergonomically to ensure comfort when driving, and their features are planning loads and rapid evacuation of seats.

Cooling

There was a time when it was believed that the presence of air conditioning in the military machine has a negative impact on the image of the "macho soldier." The U.S. Army, for example, buying a standard commercial trucks, paying extra money for the removal of air conditioners. But summer temperatures inside vehicles in Afghanistan (and earlier in Iraq) reach over 50 ° C, and the cooling system is no longer considered as something unnecessary, but rather an integral part of the equipment for a combat mission. They are designed not so much to enhance the comfort of the crew as to maintain the temperature at which it would not have received from heat stroke during combat operations. Plus, of course, the need to prevent overheating of the growing number of important on-board electronics. While the system for the crew may alleviate the problem, they are just part of a comprehensive strategy to reduce the temperature. Cooling module must also provide a small amount, size and weight, low energy consumption, since cars have become overloaded with additional armor and fire protection systems and fire.

Cooling Systems crews used as an integral part of the integrated systems of protection against weapons of mass destruction in machines that can be sealed, and as a separate component of an integrated system of protection against weapons of mass destruction in the machines, which can be sealed, or, finally, as individual solutions for machines that do not have this option, as well as part of a conventional heating systems, ventilation and air conditioning (HVAC).

Bioquell company uses the usual cycle of evaporation cooling systems in their power 5-9 kW. The system consists of an evaporator, a compressor directly connected to the main engine, a condenser outlet flow 3.2 m3 / s, the control unit, corresponding to refrigerant hoses and wiring harnesses. The cooled air is directed to the individual crew stations to maximize cooling. The system weighs about 45 kg and has dimensions of 590x380x302 mm.

South African company Booyco Engineering has developed solutions for the control of environmental conditions, including cooling and auxiliary power units for a variety of platforms, from attack helicopters to ROOIVALK corvettes. Development of the system were used in climate control crew LCCCS (Crew Climate Control System) tank LEOPARD. This module is designed for Australia and is set in a bustle MBT LEOPARD, as well as machines for minozaschischennyh RG-31 and 155-mm self-propelled howitzers wheeled G6. RG31 system was developed at the direction of the company BAE Systems and was delivered in 2009. A system using ready made components installed under the rear seats, and uses one common filter for air recirculation and fresh air. At the trials unit issued cooling capacity of 8 kW at an ambient temperature of 55 ° C.

Trucks also require cooling. Company Red Dot Corp eg HVAC supplies modules for the family of military vehicles, medium-duty FMTV (Family of Medium Tactical Vehicles) U.S. Army.

Instead of cooling air in some wearable systems to reduce body temperature circulates chilled water. They have some advantages such as reducing the size, weight and power consumption as compared with systems HVAC, some estimates suggest that savings can reach 70%. Wearable systems also allow you to work effectively with open hatches machine or crewmember position "for sea."

One of the solutions in the field of cooling systems and equipment crew, designated ICECS (individual crew and equipment cooling systems), was developed by an Israeli company Kinetics for MBT MERKAVA 3 and 4, this system were installed in 1997. Individual cooling vests created by the air-cooled. The system has since been adopted by other countries and is currently installed on a number of platforms, including missile launchers HIMARS, self-propelled howitzer M109A6 PALADIN, as well as various types of machines MRAP.

Kinetics company manufactures three wearable systems: normal / air cooled fireproof overalls Regular / Fire Resistant Air-Cooled Overall), air-cooled overalls with NBC (NBC Protected Air-Cooled Overall) and compact air-cooled vest (Air-Cooled Compact Vest), which is designed to be worn under normal clothing or jacket.

As part of Air Warrior, last year the company received Cobham program individual cooling of the U.S. Army $ 110 million to equip the personnel of Army Aviation. The system is the first with a microclimate cooling system, which uses the method of cooling the circulating pressure system is also designed to be installed on ground vehicles. As for the personnel on board the aircraft, it was determined that the duration of the task may be safely extended to three hours or more.

The U.S. Army requested the QinetiQ's put it microclimate cooling subsystem for installation on ground systems after qualifying her for helicopters UH-60, CH-47D and OH-58D. It will install on the car and armored HMMWV digger M9, whose office for one person is very close to the motor car, which leads to very high temperatures. The system provides a cooling capacity of 324 W at an ambient temperature of 51 ° C, its mass is 58 kg.

In February, the company WL Gore & Associates (UK) Ltd. active cooling system launched GORE. It is worn system created to meet the thermal standards, including British DefStd 00-35 (climate A1, A2, A3 & B2). Worn as a vest, the system provides cooling of the body directly, and works in conjunction with body armor, it is connected via a hose to the machine's cooling system. Insulation systems and sealed, and designed so that it can easily be removed in case of emergency.

Microclimate cooling system used for personal cooling and reduce thermal effects on individuals exposed to high temperatures or wearing clothing that holds heat. Microclimate cooling system - liquid (water glyukolevaya fluid as a coolant) and consists of a set in the car cooling unit worn under the outerwear cooling vest and connecting tubes with integrated control device

0

4.5K

3

Thread Digembok

Urutan

Terbaru

Terlama

Thread Digembok

Komunitas Pilihan